|

Fishing Sinker Patents

PATENT ABSTRACTS OF JAPAN

- SPHERE WITH HIGH SPECIFIC GRAVITY

- SINKER OF FISHING TACKLE

- SINKER FOR FISHING GEAR PRODUCED BY USING TUNGSTEN AND TUNGSTEN ALLOY OF INDUSTRIAL WASTE

- FISHING SINKER

- WEIGHT FOR FISHING

- FISHING SINKER

- SPLIT SHOT SINKER AND METHOD OF PRODUCING THE SAME

- SINKER FOR FISHING

- WEIGHT FOR FISHING GEAR, AND APPLICATION AND PRODUCTION OF THE SAME

- SINKER FOR FISHING TACKLE USING BIODEGRADABLE PLASTIC RESIN

- SINKER FOR FISHING TACKLE

- MANUFACTURE OF TUNGSTEN-FILLED THERMOPLASTIC RESIN PELLET FOR INJECTION MOLDING

- SINKER FOR FISHING TOOL

- MATERIAL USABLE FOR BULLET OR WEIGHT MADE OF KONNYAKU POWDER AND TOXIC METAL POWDER AND MANUFACTURE THEREOF

- SINKER FOR FISHING, AND METHOD FOR PRODUCING THE SAME

- TRANSPARENT SINKER WITH LOW SPECIFIC GRAVITY

- FISHING SINKER

- FISHING SINKER EQUIPPED WITH MEMBER FOR ADJUSTING SINKING SPEED IN WATER AND ITS PRODUCTION

- FISHING SINKER

SPHERE WITH HIGH SPECIFIC GRAVITY

| (11) Patent Publication number : |

2000-154256 |

| (43) Date of publication of patent application : |

06.06.2000 |

| (51) Int.CI.

C08J 5/00 A01K 95/00 C08K 3/08 C08L101/16

F42B 12/72 // B29C 45/00 B29K105:06 B29K505:00

B29L 31:00

|

| (21) Patent Application number : |

10-331254 |

(71) Patent Applicant : |

HIGASHIFUJI MANUF LTD |

| (22) Date of filing : |

20.11.1998 |

(72) Patent Inventor : |

MORIBAYASHI MUTSUMI |

Abstract:

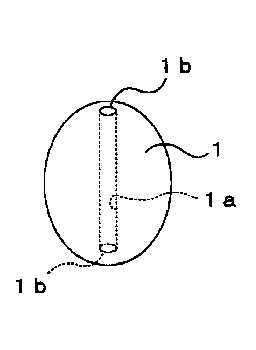

PROBLEM TO BE SOLVED: To obtain a sphere which can substitute for a

high-sepcific-gravity sphere made of lead, a hard metal, or the like by

mixing a tungsten powder mainly comprising primary particles with a

thermoplastic resin or elastomer in a specified ratio and injection

molding the resultant mixture so that the specific gravity of the

resultant molded item is a specified value.

SOLUTION:

A mixture mainly comprising 45-75 vol.% tungsten powder which is

obtained by cracking agglomerates occurring in the production process

and mainly comprises primary particles and 25-55 vol.% thermoplastic

resin or elastomer is molded so that a molded item with a specific

gravity of 9-15 is obtained. The use of a biodegradable resin as the

thermoplastic resin is environmentally preferable since it gives a

sphere which decomposes even when left behind as a bullet or a fishing

sinker in a mountain or in the sea. The surface of the sphere may be

coated with e.g. a fluororesin, graphite,

or molybdenum disulfide to improve the heat resistance or slipperiness.

Thus, the spheres can be mass-produced at a high precision.

|

SINKER OF FISHING TACKLE

| (11) Patent Publication number : |

2004-113034 |

| (43) Date of publication of patent application : |

15.04.2004 |

| (21) Patent Application number : |

2002-278078 |

(71) Patent Applicant : |

MATSUSHITA ELECTRIC IND CO LTD |

| (22) Date of filing : |

24.09.2002 |

(72) Patent Inventor : |

FUNATO YASUSHI |

Abstract:

Abstract:

PROBLEM TO BE SOLVED: To provide a sinker which is used for a fishing tackle, has a large fish-luring

effect, can easily be used, and holds the approximately same

fundamental functions, even when the shape of the sinker is larger than

a conventional sinker made from lead.

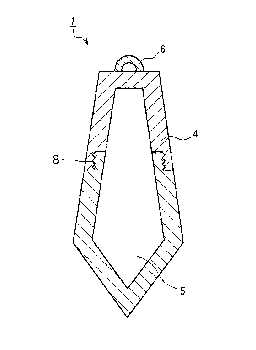

SOLUTION: This sinker (1) used for the fishing tackle, holding a

fish-luring

substance in a sinker main body portion (4) and comprising an

environmentally harmless metal material is characterized in that the

metal material is at least one selected from porous tungsten having

many open pores therein and porous tungsten heavy alloys having many

open pores therein and further that the open pores can be impregnated

with the fish-luring substance. The fish-luring

substance is gradually scattered from the inner hollow portion (5)

through the open pores for making the front side of the sinker main

body portion to communicate with the back side.

|

SINKER FOR FISHING GEAR PRODUCED BY USING TUNGSTEN AND TUNGSTEN ALLOY OF INDUSTRIAL WASTE

| (11) Patent Publication number : |

2003-061514 |

| (43) Date of publication of patent application : |

04.03.2003 |

| (51) Int.CI.

A01K 75/06 A01K 95/00

|

| (21) Patent Application number : |

2001-253098 |

(71) Patent Applicant : |

AZUMAYA:KK |

| (22) Date of filing : |

23.08.2001 |

(72) Patent Inventor : |

URUSHIYA YUKICHI |

Abstract:

Abstract:

PROBLEM TO BE SOLVED: To develop a method for the reutilization of

tungsten and tungsten alloy from an industrial waste containing the

metal or metal alloy.

SOLUTION: Cut scraps of tungsten and tungsten alloy and chips, bites

and drill teeth of the cutware of tungsten, etc., are useless as a raw

material for the recovery of metallic tungsten

or impossible to reuse as a reclaimed material by processing and,

accordingly, disposed as an industrial waste. The metal or metal alloy

is formed by using a resin as a binder and the formed resin material is

used as a material of a sinker for fishing gear.

|

FISHING SINKER

| (11) Patent Publication number : |

2002-335838 |

| (43) Date of publication of patent application : |

26.11.2002 |

| (21) Patent Application number : |

2001-144562 |

(71) Patent Applicant : |

DAIWA SEIKO INC |

| (22) Date of filing : |

15.05.2001 |

(72) Patent Inventor : |

SHOJI KIMITAKE |

Abstract:

Abstract:

PROBLEM TO BE SOLVED: To provide a fishing sinker enabling the many

movements, easy attachments/detachments of a fishing line without

damaging a fishing line.

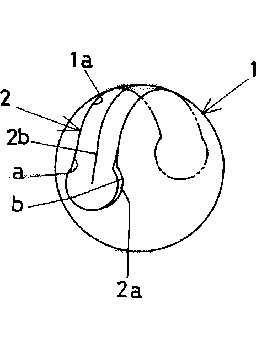

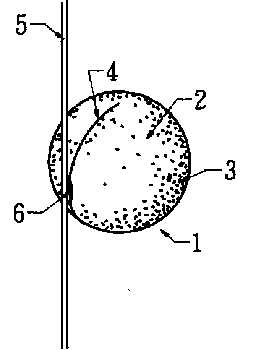

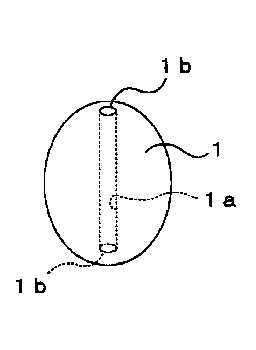

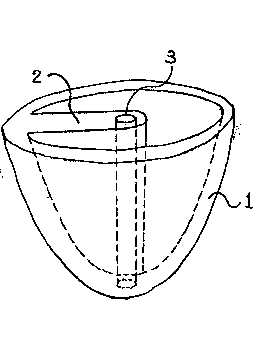

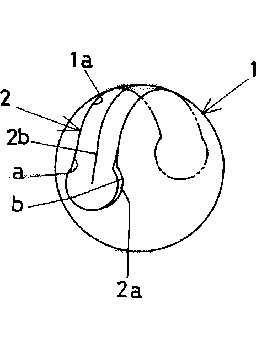

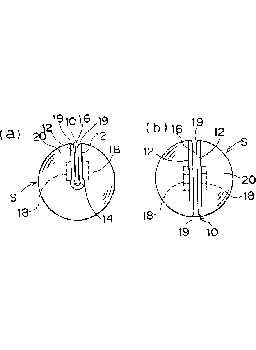

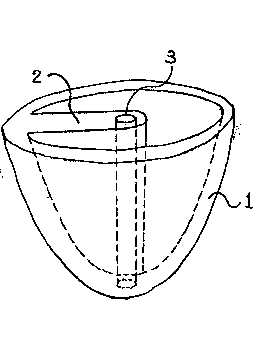

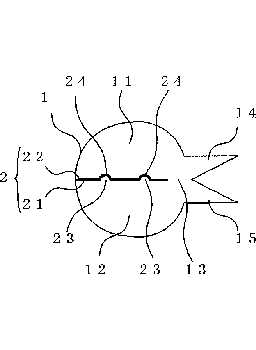

SOLUTION: This fishing sinker is composed of a sinker main body 1

having a spherical outer shape and a nipping member 2 having a sliced

boiled fish paste (Kamaboko) shape. The sinker main body 1 is produced

from a metal having a specific gravity of ≥7 such as tungsten, a

tungsten

alloy, an iron-based metal such as stainless steel, or a copper alloy.

An elastomer for forming the nipping member 2 is formed from an easily

deformable material having lower hardness than that of the sinker main

body 1, and a polymer material such as a rubber, a synthetic rubber or

a synthetic resin is used as the easily deformable material. A slitting

groove 1a is formed in the sinker main body 1 in a spherical shape, and

the slitting groove 1a is formed in a flask cross section shape having

vertical planes (a) and a circular shape (b), and the circular shape

(b) is used as a portion for engaging the nipping member 2. Projections

from the sinker main body 1 are formed on both the sides of the nipping

member 2, and a slit 2b is formed on the center of thickness of the

knitting member 2.

|

WEIGHT FOR FISHING

| (11) Patent Publication number : |

2002-291389 |

| (43) Date of publication of patent application : |

08.10.2002 |

| (21) Patent Application number : |

2001-104167 |

(71) Patent Applicant : |

DAIWA SEIKO INC |

| (22) Date of filing : |

03.04.2001 |

(72) Patent Inventor : |

SHOJI KIMITAKE |

Abstract:

Abstract:

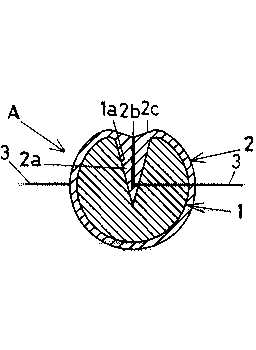

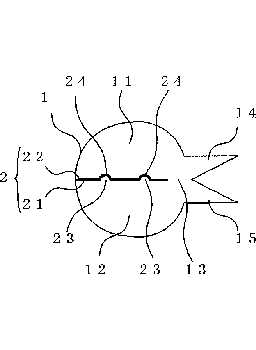

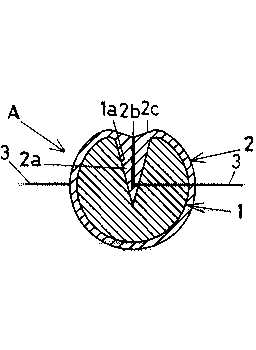

PROBLEM TO BE SOLVED: To enable transfer and detachment of a weight many times without damaging fishline.

SOLUTION: A V-shaped groove 1a is formed from the outside of a globular weight body 1 of the weight A for fishing

toward the centerline passing through the central point of the weight

body 1 in the weight body 1 and the outside of the weight body 1 is

covered with an elastic material to form an elastic layer 2 and the

elastic material is packed also into the groove 1a to form a packed

part 2a and a slit 2b is formed in the packed part 2a. The depth of the

slit 2b reaches the vicinity of position of the centerline passing

through the central point of the weight body 1. A metal having ≥7

specific gravity, e.g. an iron-based metal such as tungsten, tungsten

alloy or stainless, or copper alloy is used as the weight body 1 and a

polymeric material such as rubber, synthetic rubber or synthetic resin

composed of a material having lower hardness than hardness of the

weight body 1 is used as the elastic material forming the elastic layer

2 and when the weight A for fishing is

held by a fishline 3, the weight A is held by pushing the fishline 3

into the slit 2b, preferably by pushing the fishline 3 into the

vicinity of centerline position passing through the center of the

weight body 1.

|

FISHING SINKER

| (11) Patent Publication number : |

2002-084948 |

| (43) Date of publication of patent application : |

26.03.2002 |

| (21) Patent Application number : |

2000-275861 |

(71) Patent Applicant : |

GAMAKATSU CO LTD |

| (22) Date of filing : |

12.09.2000 |

(72) Patent Inventor : |

SANO KAZUNORI |

Abstract:

Abstract:

PROBLEM TO BE SOLVED: To obtain a fishing sinker capable of preceisly

adjusting buoyancy of a terminal tackle and not damaging a fishing line.

SOLUTION: This fishing sinker comprises an elastic substance having an

elasticity in curing and tungsten powder and is obtained by compounding

the substance with the tungsten powder before curing, then curing and

molding and forming a slit narrower than the width of a fishing line.

|

SPLIT SHOT SINKER AND METHOD OF PRODUCING THE SAME

| (11) Patent Publication number : |

2001-275537 |

| (43) Date of publication of patent application : |

09.10.2001 |

| (21) Patent Application number : |

2000-188313 |

(71) Patent Applicant : |

GAIN CORPORATION:KK |

| (22) Date of filing : |

22.06.2000 |

(72) Patent Inventor : |

MIURA SHINJI

SASAKI YOSHIHIRO

KUMON AKIRA |

Abstract:

Abstract:

PROBLEM TO BE SOLVED: To provide a split shot sinker scarcely causing a

fishing line to be broken, effective for preventing environmental

pollution, and capable of being easily produced.

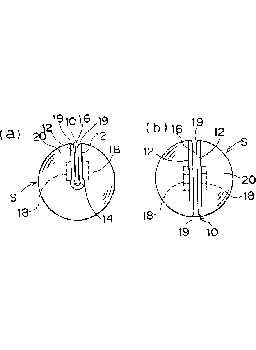

SOLUTION: This split shot inker S has a slit 16 into which the fishing

line L is inserted, wherein the sinker is composed of a sinker body 20

made of a material having a high relative density, and further composed

of a slit material 10 which is embedded in the sinker body 20,

positioned in an area with which the fishing line L is contacted, forms

the slit 16, and is made of a resin material having flexibility. The

fishing line L is difficult to be broken, because the slit material 10

contacts with the fishing

line. Even when a metal which does not give any anxiety about the

environmental pollution but is too hard to be flexibly deformed, such

as tungsten, is used as the sinker body 20, fastening operation of the

fishing line L can be carried out, because the slit 16 of the slit

material 10 made of the resin material is easily deformable.

|

SINKER FOR FISHING

| (11) Patent Publication number : |

2001-120139 |

| (43) Date of publication of patent application : |

08.05.2001 |

| (21) Patent Application number : |

11-302260 |

(71) Patent Applicant : |

SHIMURA MASABUMI |

| (22) Date of filing : |

25.10.1999 |

(72) Patent Inventor : |

SHIMURA MASABUMI |

Abstract:

Abstract:

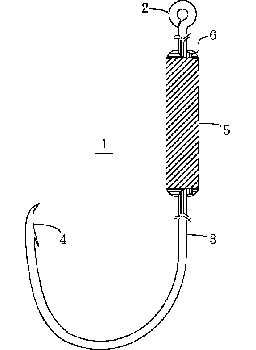

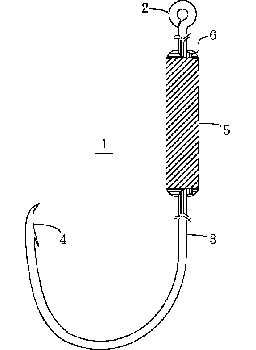

PROBLEM TO BE SOLVED: To provide a sinker for fishing preventing

pollution of a river and damage to fishes, birds, etc., caused by lead

used as a sinker in a fishing hook, extending flying distance of the

fishing hook and capable of raising sinking speed by utilizing a lower

specific gravity than lead and enabling to obtain a good fishing

result.

SOLUTION: The fishing hook provided with a fishing line holding part

holding fishing line, a curved fishing hook body extending from the

fishing line holding part and a point part to catch a fish, has a

tungsten sinker installed at the upper part of the fishing hook body

part.

|

WEIGHT FOR FISHING GEAR, AND APPLICATION AND PRODUCTION OF THE SAME

| (11) Patent Publication number : |

2001-069891 |

| (43) Date of publication of patent application : |

21.03.2001 |

| (51) Int.CI.

A01K 95/00 A01K 85/00

|

| (21) Patent Application number : |

11-259352 |

(71) Patent Applicant : |

CRYSTAL KOGAKU:KK |

| (22) Date of filing : |

13.09.1999 |

(72) Patent Inventor : |

SASAKI YOSHIHIRO

KIRINO SHIGERU

ICHIDA AKIRA

TAKITA TOMOHIRO

TAKAOKA SHIGEHIKO

OKAMOTO KENICHI |

Abstract:

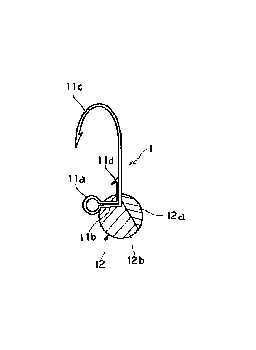

Abstract:

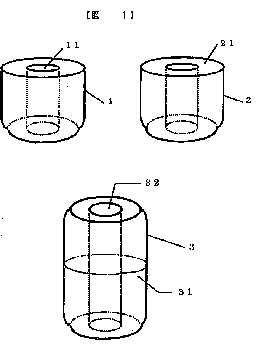

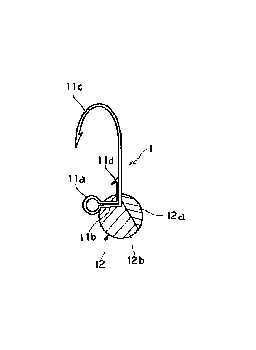

PROBLEM TO BE SOLVED: To obtain a fishing

weight which is easily producible, less expensive and easily

processable into a soft lure, and further which has a high specific

gravity by molding a specific metal-resin combined powder under heating

and compressing.

SOLUTION: A weight 12 for a fishing

gear produced by molding a metal- resin combined powder under heating

and compressing. The metal-resin combined powder is prepared by coating

metal particles substantially free from lead, zinc and tin with a

resin, and it consists of combined particles having a specific gravity

of 11-16. The metal particles are preferably composed of tungsten

and/or its alloy. Further, in a jig-head 1 having a weight part which

wraps the root of a fishhook in such a manner that the fishhook and its

eye 11a are exposed, and which is integrated with the fishhook, the

weight part can be the above-mentioned weight 12 for fishing gear.

|

SINKER FOR FISHING TACKLE USING BIODEGRADABLE PLASTIC RESIN

| (11) Patent Publication number : |

2000-201606 |

| (43) Date of publication of patent application : |

25.07.2000 |

| (21) Patent Application number : |

11-045237 |

(71) Patent Applicant : |

TOOMIKKU:KK |

| (22) Date of filing : |

18.01.1999 |

(72) Patent Inventor : |

MIYAZAKI TAKASHI |

Abstract:

PROBLEM TO BE SOLVED: To provide a sinker for fishing

tackles using a biodegradable plastic resin letting the sinker manifest

excellent performance durably while being used, being able to be

decomposed by natural microorganisms after abandonment, finally

becoming soil organic ingredients, carbon dioxide and water, and not

remaining and not being accumulated in the environment.

SOLUTION: This sinker for fishing

tackles using a biodegradable plastic resin is characterized by being

made of a mixture of a high specific gravity metal such as tungsten

having a higher specific gravity than that of lead with a biodegradable

plastic resin and then by being made capable of being linked with a fishing line.

|

SINKER FOR FISHING TACKLE

| (11) Patent Publication number : |

2000-157129 |

| (43) Date of publication of patent application : |

13.06.2000 |

| (21) Patent Application number : |

10-334210 |

(71) Patent Applicant : |

MITSUBISHI MATERIALS CORP |

| (22) Date of filing : |

25.11.1998 |

(72) Patent Inventor : |

SAKAI MASAAKI

KOBAYASHI MASAHARU

HATTORI KENYA |

Abstract:

Abstract:

PROBLEM TO BE SOLVED: To obtain the subject sinker miniaturized with

reduced volume and affording a specific gravity greater than that of

lead optimum as a sinker by molding to a specified specific gravity a

composition mainly comprising tungsten (alloy) and a thermosetting resin.

SOLUTION:

This sinker is obtained by molding to a specific gravity of 11-17 a

composition mainly comprising pref. 20-35 vol.% of a thermosetting

resin and tungsten or its alloy (pref.

W-Ni-Cu-based alloy, W-Ni-Fe-based alloy, or the like; specifically,

W-6Ni-4Cu, W-3Ni-2Cu, W-1.8Ni-1.2Cu, W-4.9Ni-2.1Fe, W-3.5Ni-1.5Fe, or

the like). This sinker is attached to the tip of the line of a fishing tackle.

|

MANUFACTURE OF TUNGSTEN-FILLED THERMOPLASTIC RESIN PELLET FOR INJECTION MOLDING

| (11) Patent Publication number : |

11-333837 |

| (43) Date of publication of patent application : |

07.12.1999 |

| (51) Int.CI.

B29B 9/00 B29B 9/12 B29B 13/10 // B29K 23:00 B29K105:16 B29K503:06

|

| (21) Patent Application number : |

10-158627 |

(71) Patent Applicant : |

SUZUKI SHOICHI |

| (22) Date of filing : |

22.05.1998 |

(72) Patent Inventor : |

SUZUKI SHOICHI |

Abstract:

PROBLEM TO BE SOLVED: To provide a method for manufacturing a

tungsten-filled thermoplastic resin pellet used to mold a high specific

gravity product such as a weight for fishing, sports equipment such as

dumb-bell, barbell, paper weight or the like by an injection molding

machine.

SOLUTION: The method for manufacturing a tungsten-filled thermoplastic

resin pellet comprises the steps of kneading powder tungsten

having a particle size of 2 to 5 microns and a small amount of wax with

an olefin elastomer resin by kneading rollers while heating it at about

160°C to obtain a uniform mixture, forming the mixture in a

plate-like

state, and then comminuting it by a comminutor to the pellet.

|

SINKER FOR FISHING TOOL

| (11) Patent Publication number : |

10-286052 |

| (43) Date of publication of patent application : |

27.10.1998 |

| (21) Patent Application number : |

09-099377 |

(71) Patent Applicant : |

BASUDEI KK |

| (22) Date of filing : |

16.04.1997 |

(72) Patent Inventor : |

ITO KIYOSHI

YAMAGISHI NOBUYUKI |

Abstract:

Abstract:

PROBLEM TO BE SOLVED: To obtain a sinker for a fishing tool,

constituted in small size and heavy in weight, not damaging the natural

world.

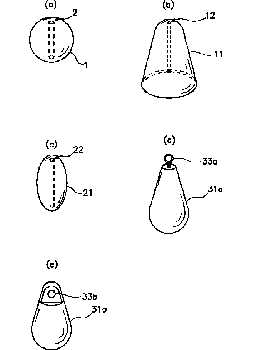

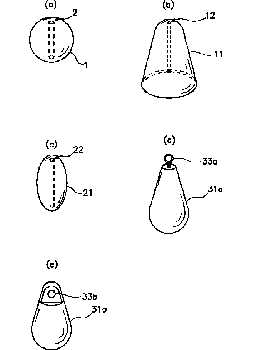

SOLUTION: The sinkers 1, 11, 21, 31a and 31b for a fishing tool is

constituted of an alloy by adding nickel and iron or copper to tungsten

so as to make a specific gravity ≥17. The alloy is made by sintering

by

powder metallurgy. These sinkers have corrosion resistance, do not

damage the natural world and can be reduced in volume.

|

MATERIAL USABLE FOR BULLET OR WEIGHT MADE OF KONNYAKU POWDER AND TOXIC METAL POWDER AND MANUFACTURE THEREOF

| (11) Patent Publication number : |

08-200998 |

| (43) Date of publication of patent application : |

09.08.1996 |

| (51) Int.CI.

F42B 7/00 A01K 95/00

|

| (21) Patent Application number : |

07-014212 |

(71) Patent Applicant : |

NAGUMO SHIGEJI

GUNRITSU KIKI KK

IMAIZUMI YUJI |

| (22) Date of filing : |

31.01.1995 |

(72) Patent Inventor : |

NAGUMO SHIGEJI |

Abstract:

Abstract:

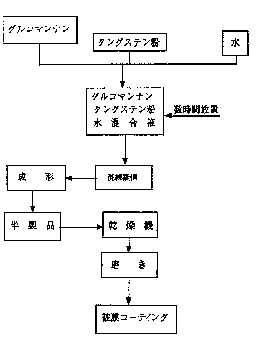

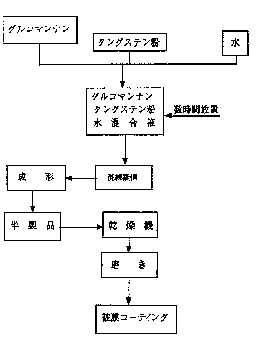

PURPOSE: To eliminate public pollution even if a material made of

konnyaku or gelatinous food made from devil's-tongue starch powder and

non-toxic metal powder of predetermined amount with respect to the

konnyaku as a bullet, finishing weight, etc., is left to stand in

natural field after using by using the material as the bullet, the fishing weight, etc.

CONSTITUTION: A kg of konnyaku powder, 0.5A to 5Akg of non-toxic metallic powder (tungsten

powder) and 5A to about 40Akg of water are mixed, the mixed solution is

left to stand for about 2 to three hours. Then, the solution thus left

to stand is agitated without irregularity, glucomannan is solidified,

and then solidified konnyaku powder is filled in a predetermined mold

to be molded. Thereafter, the molding is filled in a dryer to extract

its moisture, and the shape is arranged. As required, a film coating is

provided. When the bullet or the weight is left to stand for about one

week, it is corroded to be returned to soil. The bullet or the weight

flowing to the river is returned to the water in 5 to 30 days. Thus,

even if it is left to stand after the use, there is no anxiety of

public pollution.

|

SINKER FOR FISHING, AND METHOD FOR PRODUCING THE SAME

| (11) Patent Publication number : |

2004-024263 |

| (43) Date of publication of patent application : |

29.01.2004 |

| (21) Patent Application number : |

2003-180729 |

(71) Patent Applicant : |

WATER GREMLIN CO |

| (22) Date of filing : |

25.06.2003 |

(72) Patent Inventor : |

RATTE ROBERT W |

Abstract:

Abstract:

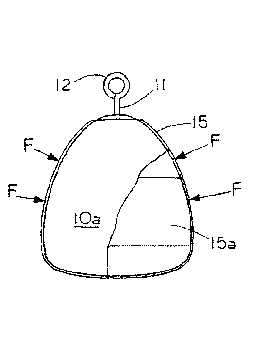

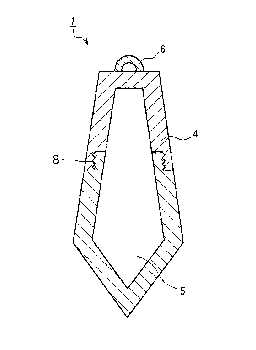

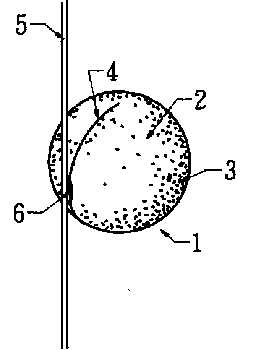

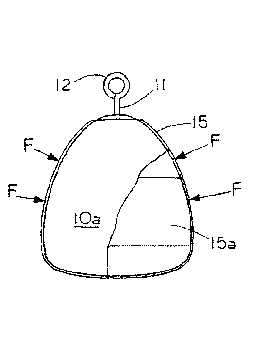

PROBLEM TO BE SOLVED: To provide a sinker for fishing comprising a brittle metal and to provide a method for producing the same.

SOLUTION: The material for the sinker body has a sufficient specific gravity for using as the sinker (10) for fishing,

and has an outside casing, namely, a skin cover (15) fitting to the

outer surface (10a) of the body to prevent crushing of the body and

preventing loss of the material in the case of crushing. The casing can

be provided with a visible indicator to help a user identify the type

of sinker and dimension or other information thereof.

|

TRANSPARENT SINKER WITH LOW SPECIFIC GRAVITY

| (11) Patent Publication number : |

2002-045097 |

| (43) Date of publication of patent application : |

12.02.2002 |

| (21) Patent Application number : |

2000-270809 |

(71) Patent Applicant : |

CEL:KK |

| (22) Date of filing : |

03.08.2000 |

(72) Patent Inventor : |

IKEDA MASATOSHI |

Abstract:

Abstract:

PROBLEM TO BE SOLVED: To provide a means for simultaneously achieving

tightening of a fishline and synchronization with chum or attractant by

using a transparent sinker with a low specific gravity because the

conventional sinker attached to the vicinity of a fishhook is mainly

composed of a metal (e.g. lead) and has a large specific gravity to

cause crimp or bend to the flow and not to be readily synchronized with

the chum.

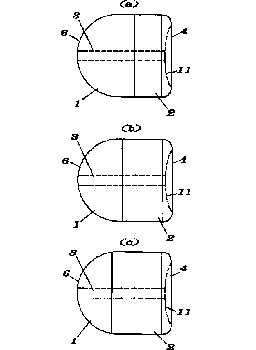

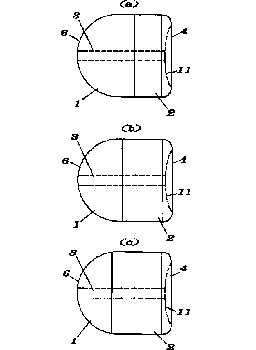

SOLUTION: This transparent sinker with the low specific gravity is

characterized in that a half-cone body is formed out of a transparent

material having >1.0 specific gravity,

and a through hole 3 allowing the fishline to penetrate the hole 3 from

the vicinity of the tip bottom part of the half-cone body to the

vicinity of the top center comprising a flat surface, a concave part or

the like. The transparent sinker with the low specific gravity can be

attached to a part very close to a fishhook without calling attention

of a fish because of the transparency, and hardly provides a node-like

crimp to the fishline because of the low specific gravity. The sinker

also can facilitate the catch of strike because the flat surface or the

concave part of the upper part receives the force of the stream to make

the fishline tight, and can allow the chum or the attractant to be

synchronized with the fishhook and prevent the terminal tackle from

being entangled because the terminal tackle is directly pulled by the

flow. A transparent high-molecular material and glass having >1

specific gravity is cited as the material.

|

FISHING SINKER

| (11) Patent Publication number : |

2001-086910 |

| (43) Date of publication of patent application : |

03.04.2001 |

| (21) Patent Application number : |

11-307425 |

(71) Patent Applicant : |

MAMIYA OP CO LTD |

| (22) Date of filing : |

22.09.1999 |

(72) Patent Inventor : |

TACHIHARA SHIRO |

Abstract:

Abstract:

PROBLEM TO BE SOLVED: To obtain a fishing sinker made of a

high-specific gravity synthetic resin capable of readily nipping a

fishing line without separately equipping a main body with a hinge

means, etc.

SOLUTION: This fishing sinker is obtained by equipping a main body 1 of

the fishing sinker, composed of a high-specific-gravity resin made to

have a high specific gravity by compounding a flexible resin with a

high-specific- gravity metal, with a slit 2 capable of nipping a

fishing line, closable by the restoring force of the

high-specific-gravity resin and openable by applying an external force

to the main body.

|

FISHING SINKER EQUIPPED WITH MEMBER FOR ADJUSTING SINKING SPEED IN WATER AND ITS PRODUCTION

| (11) Patent Publication number : |

2000-189020 |

| (43) Date of publication of patent application : |

11.07.2000 |

| (21) Patent Application number : |

10-376177 |

(71) Patent Applicant : |

IBARAGI SEISAKUSHO:KK |

| (22) Date of filing : |

22.12.1998 |

(72) Patent Inventor : |

IBARAKI MASAHIKO |

Abstract:

Abstract:

PROBLEM TO BE SOLVED: To provide a fishing sinker

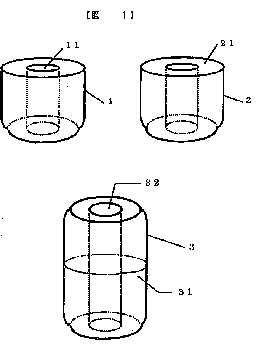

capable of enlarging a casting distance on bait casting and capable of

adjusting and assisting the sinking speeds of a lure and a bait.

SOLUTION: This fishing sinker is obtained by integrally attaching an

adjusting member 2 to a sinker body 1 formed from a lightweight

material whose specific gravity is smaller by 3.0-15.0% than that of

water, thus forming the sinker

which is wholly heavier by 1.5-4.5 times than that of the water. The

adjusting member 2 is formed from a heavy material having a larger

specific gravity by 7.5-8.0 times that of water.

|

FISHING SINKER

| (11) Patent Publication number : |

10-042763 |

| (43) Date of publication of patent application : |

17.02.1998 |

| (21) Patent Application number : |

08-218014 |

(71) Patent Applicant : |

YAMASHITA:KK |

| (22) Date of filing : |

31.07.1996 |

(72) Patent Inventor : |

YAMASHITA SEIJI |

Abstract:

PROBLEM TO BE SOLVED: To provide a fishing sinker to be attached to a

terminal tackle and a lure, capable of making a fisherman enjoy fishing

in the sea, a lake, a river, etc., without destroying a natural

environment.

SOLUTION: This fishing sinker is made of a ceramic material having a high specific gravity.

|

|

Abstract:

Abstract: Abstract:

Abstract: Abstract:

Abstract: Abstract:

Abstract: Abstract:

Abstract: Abstract:

Abstract: Abstract:

Abstract: Abstract:

Abstract: Abstract:

Abstract: Abstract:

Abstract: Abstract:

Abstract: Abstract:

Abstract: Abstract:

Abstract: Abstract:

Abstract: Abstract:

Abstract: